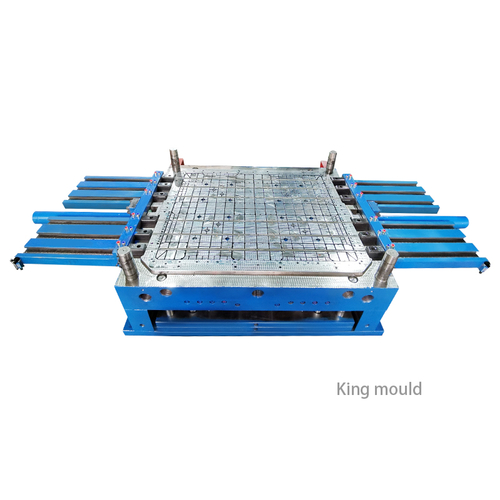

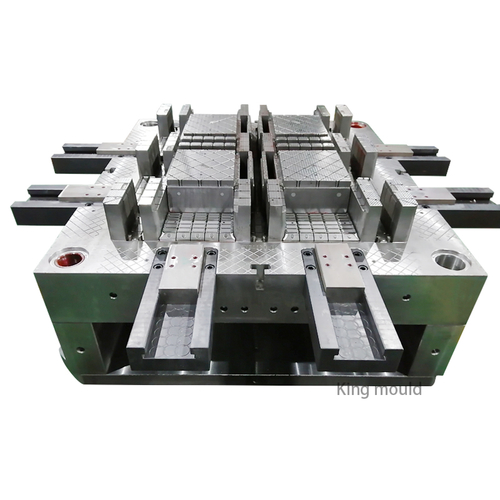

Custom Cheap Molded Wood Double Face Mould Injection Pallets Price

In industries where materials need to be transported efficiently, the design and production of pallets play a critical role. One such design that has gained popularity is the double face pallet mould . This innovative mould design provides enhanced load stability, making it a preferred choice for many businesses. By manufacturing pallet moulds, manufacturers can create pallets that offer better load distribution and stability, reducing the risk of damage during transportation. This article explores the benefits and the manufacturing process behind Custom double face pallet moulds.

A double face pallet mould is a mould used to create pallets that have two usable surfaces, each providing load-bearing support. This design allows for more versatile use, as the pallet can be turned over to extend its lifespan and distribute loads more evenly. The pallet mould design often features two flat surfaces with uniform dimensions, providing consistent load support regardless of how the pallet is oriented. This is particularly useful in industries where pallets undergo frequent handling and need to withstand significant loads.

The primary advantage of using double face pallet moulds is the enhanced load stability they offer. Traditional pallets with a single face can wear out more quickly due to uneven wear, especially when the same side is used repeatedly. In contrast, a pallet mould produces a product that can be flipped over, essentially doubling its effective surface area. This feature improves load distribution and prevents one side from deteriorating prematurely.

Moreover, Cheap Molded Wood Pallets can increase the pallet's strength and durability. The uniform thickness and design of the mould help ensure that the pallet remains stable under heavy loads. As a result, products stored or transported on double face pallets are less likely to shift or become damaged during handling, making them ideal for heavy-duty applications.

The materials used to manufacture double face pallet moulds are crucial to their performance. Typically, high-strength steels are used for the moulds due to their ability to withstand the pressure and heat during the injection molding process. Steel also provides longevity, ensuring the moulds last through numerous production cycles. In some cases, aluminum may be used for lighter applications, though steel remains the popular material for double face pallet moulds due to its strength and durability.

Additionally, the choice of raw materials for the pallets themselves is equally important. Plastic, wood, or metal can all be molded into the shape of double face pallets, but plastic pallets made from durable polyethylene are commonly produced using double face pallet moulds due to their light weight, resistance to moisture, and ease of handling.

Manufacturers who use double face pallet moulds benefit from increased efficiency and product quality. The durability of the pallets produced from these moulds reduces the need for frequent replacements, resulting in long-term cost savings. Furthermore, the improved stability of double face pallets reduces product damage, which is essential for businesses involved in transporting delicate or high-value items.

In addition, the versatility of double face pallets makes them adaptable for various industries, including food, pharmaceuticals, and manufacturing. Their ability to support large, heavy loads while maintaining stability makes them ideal for heavy-duty environments, while the option to flip the pallet extends its lifespan, ensuring consistent performance over time.

The manufacturing of Injection Pallet Price provides significant benefits for businesses involved in logistics and material handling. By creating pallets with two usable faces, these moulds enhance load stability, reduce wear, and increase the overall durability of the pallets. This ultimately results in better protection for products, fewer replacements, and improved efficiency in supply chain operations. The manufacturing process of double face pallet moulds ensures that pallets are produced with high precision and can withstand the demands of various industries. As industries continue to prioritize stability, efficiency, and cost-effectiveness, double face pallet moulds will remain a vital part of the production process.

English

English عربى

عربى